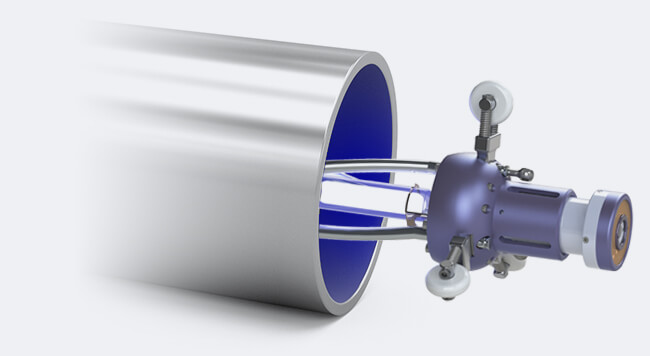

nUVision

UV light curing of hose liners even in the case of extremely long pipe supportsThe revolutionary technology with up to 1,000 m cable length.

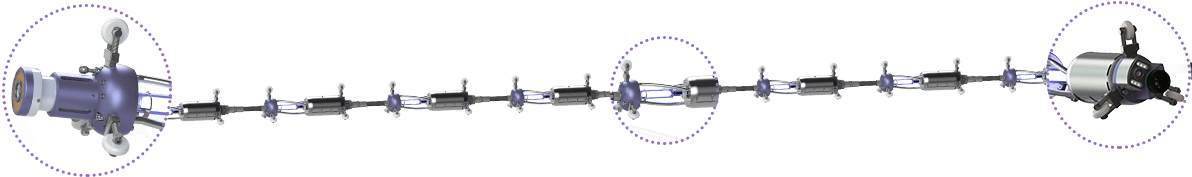

The patent-protected nUVision technology with up to 1,000 m cable length allows complete control of the curing process based on a BUS control with up to 54 temperature values, intensity monitoring of the UV lamps (2-18 lamps configurable by modular design) and 2 HD video signal recordings. Each module has its own sensor technology.

The benefits at a glance

- Revolutionary ignition technology

- Cable length extension up to 1,000 meters possible

- Simultaneous video recordings of front and back eye camera images in high quality HD

- No temperature problems with the cable or cable drum

- Reduction of control cabinet size by more than half

- Infinitely variable output up to 2,000 watts per lamp

- Optimal quality control of the curing process at every position of the liner

- The individual modules of the light chain can be plugged as needed

- BUS system for continuous data transmission of all curing parameters

Bus technology

- The BUS system that provides full transparency at all times during the curing process:

- Internal pressure, IR surface measurement of the liner

- Ambient air measurement at each radiator

- Operating status of each individual radiator, current, voltage and system temperature

- Continuous UV intensity measurement at each individual lamp

- Varied representation of polymerization parameters / diagrams / temperature curves during operation

- Permanent quality control

Remote service for repair or troubleshooting

nUVision compact system

This revolutionary technology is also available in a very compact design with all the features of the large nUVision system, but mobile, lightweight and transportable even in less accessible locations.