Power LIGHT

The I.S.T. modular system for demanding tasksThe system for

curing polyester resin-impregnated hose liners

The multifunctional system with perfectly matched modules for curing UV light reactive, polyester resin impregnated hose liners. Numerous configuration options offer adaptability to virtually all tasks for pipe dimensions from DN 150 to DN 1800 for circular and egg-shaped profiles.

Power LIGHT UV compact system

For smaller nominal widths and shorter holders, the Power LIGHT UV compact unit is available with a cable length of up to 200 meters.

Numerous configuration options offer adaptability to almost all tasks from DN 150 to DN 500 for circular and egg-shaped profiles. For larger nominal widths and more powerful light sources, a higher output can be achieved by using an optional booster insert.

The light source dimensions can be adapted to any liner diameter and the system offers continuous performance monitoring of the UV lamps, whose service life has been optimized with the double bulb technology used.

The light sources are equipped with front and backeye cameras for optimum monitoring of the curing process.

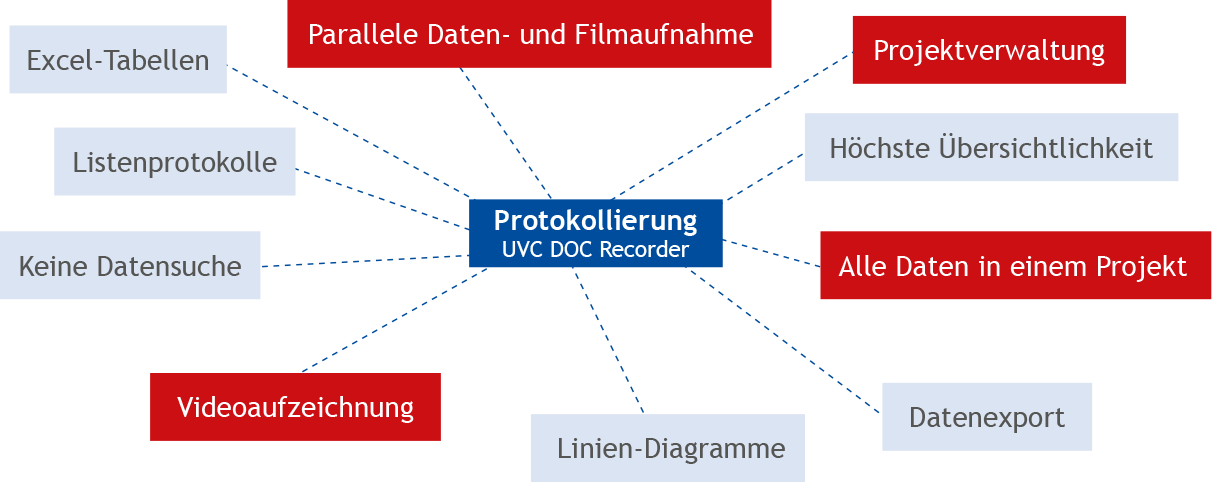

Professional control units and an innovative protocol technology that records all relevant curing data including video files make a significant contribution to quality assurance and complete the Power LIGHT system.

| Compact UV-system | Tecnical data | |

|---|---|

| Curing drum | Regulated, integrated controls / ignition functions / EMERGENCY OFF / trip-switch protected individual circuits / power units for 9 x 400 watt / up to 650‘ curing cable – motorized winding/unwinding |

| Siemens KTP 1200 S7 | Visualization of all relevant data such as 3 x IR sensors, air temperature, speed, lamp status / presentation of the front and/or back-eye camera images |

| UV doc | Industrial PC incl. high-end software |

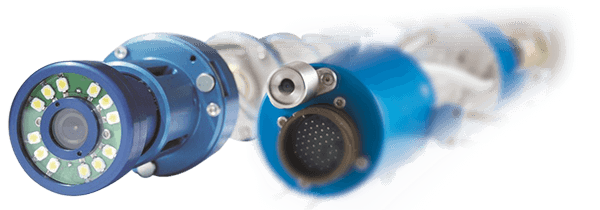

| UV-curing camera front | Diameter 24 mm / using Cree-LEDs lighting |

| Lighting source | 9 x 400 watt / wheel sets 6“ to 60“ |

| Packer | 4 pairs 6“ to 60“ / air connections / Venturi nozzles |

| Spare parts set | 400 W lamp / replacement glass LED camera lighting / replacement glass camera optics |

Controls

The Power LIGHT UV-Curing Control systems for the regulation of light chains are available in different configurations and performance classes, as well as modular equipment.

| Power LIGHT UV-Curing Control 1200 Professional | |

|---|---|

| UV light output: | Up to 18000 watts |

| Cable length: | Up to 320 m |

| Protocol: | I.S.T. UV documenting system, I.S.T. UV doc recorder/player |

| Controls: | Siemens PLC KTP 1200 S7 |

| Light source: | 9 × 400/650 watts, DN 150 - DN 600 |

| 9 × 1000 W chain / 8 × 1000 W dual-core (optional), DN 650 - DN 1500 | |

| 9 × 2000 W chain, DN 1200 - DN 1500 | |

| Camera system: | Self-leveling horizontal Front camera & Back-eye camera (incl. Back-eye lighting) |

UV curing drums

UV drums in different sizes as mobile units up to fixed versions, equipped with:

- Calibration pressure monitoring

- Pluggable connection to the system control

- Continuous position control

- Air conditioning (optional)

- System operation also possible from the KT 300 UV drum (optional)

- UV drums with cable lengths up to 320 m are available

Boosters

Three different boosters are available designed to extend the performance of the controllers:

- Booster Mini (9 x 650 Watt)

- Booster Medium (9 x 1000 Watt)

- Booster Maxi (9 x 2000 Watt)

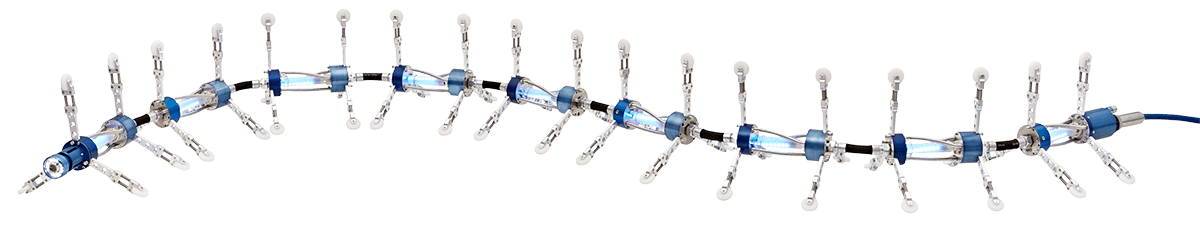

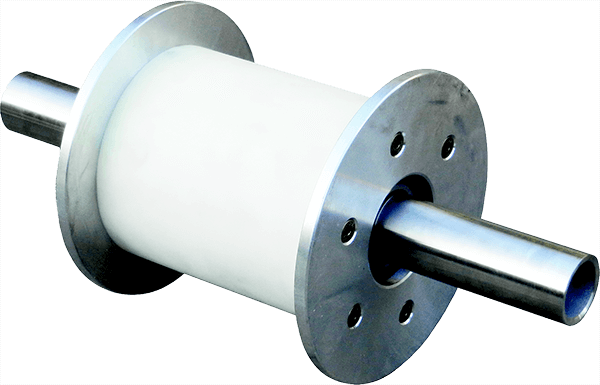

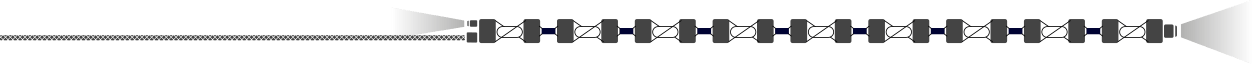

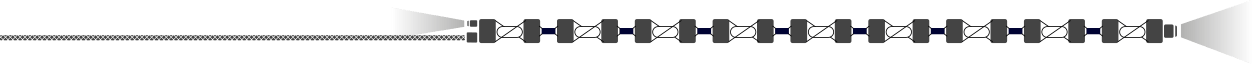

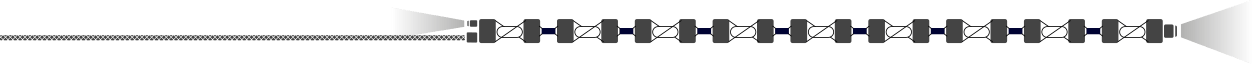

Light chains

UV light sources for different tube cross sections and shapes including egg profile geometries are available, tailored to the requirements and customer priorities.

- Equipped with front and backeye camera

- Offset arrangement of the wheels to avoid the formation of shadows

- Simple conversion for use in egg profiles

- Continuous performance monitoring of the UV lamps

- Light source dimensions adaptable to any liner diameter

- Service life of the emitters optimized thanks to double-piston technology

- Electronic blower control

Curing cameras

The front and backeye cameras are exclusively available from I.S.T. They allow full monitoring of the curing process including a horizontal self-alignment of the front camera. Both of the cameras are equipped with high-quality lighting.

Accessories

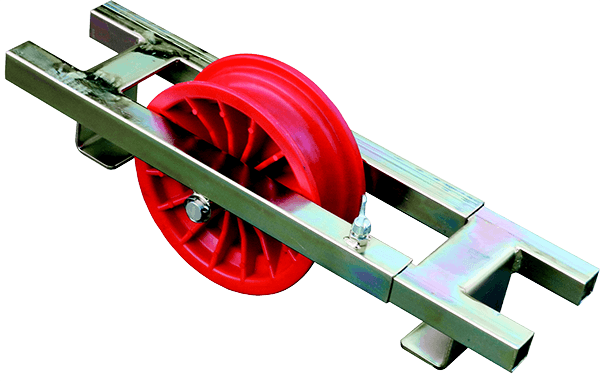

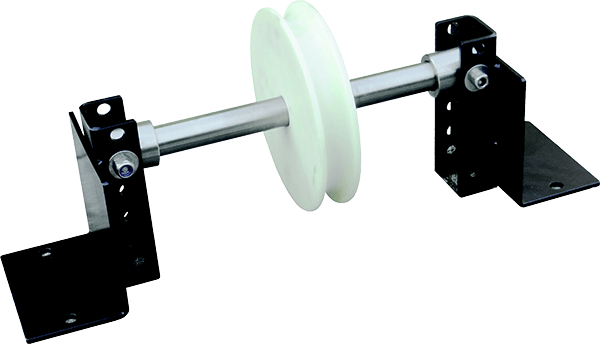

Wheelsets

Circular profile cross sections (DN 150 to DN 1600) and egg-shaped profile cross sections (DN 500 to DN 1200)

Deflections

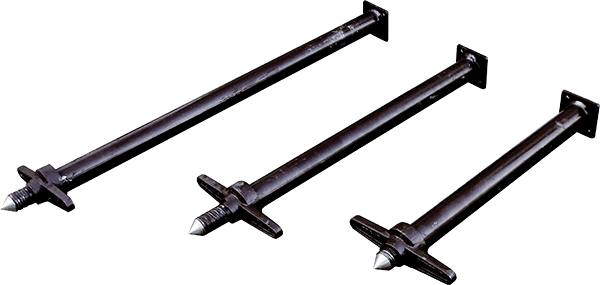

DEFLECTION RODS

Spindle spinner with outer tube

Lengths 500 mm to 1100 mm

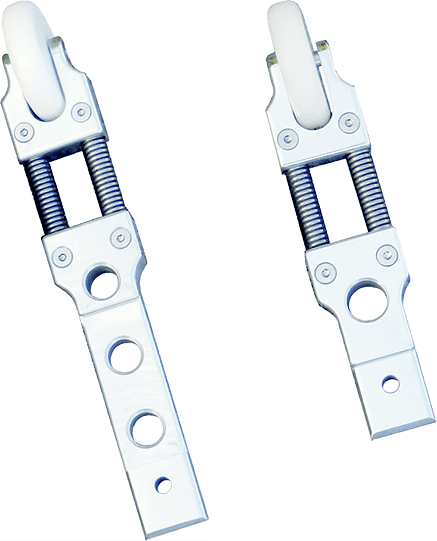

DEFLECTION ROLLERS

for shaft openings

DEFLECTION ROLLERS

for the shaft beds / berms with and without bearings

DEFLECTION ROLLERS

for film and liner feeding

Width 300 mm and 500 mm

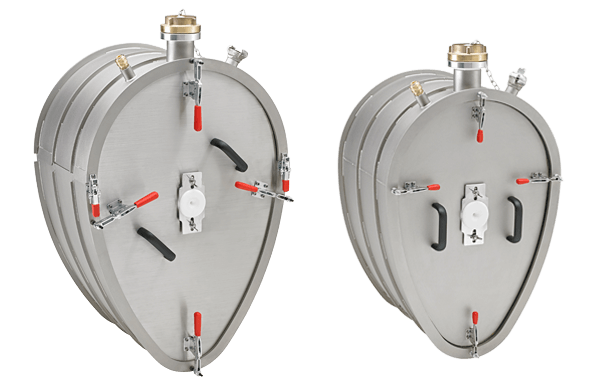

End caps

Innovative end caps (packers) are used to seal the liners. I.S.T. has all the necessary connections and their design makes them highly versatile:

- Innovative end cap technology

- The cap is sealed when pressure is applied to the liner

- Quick changing is possible

- Available for circular profile cross-sections from DN 150 to DN 1600 plus special profiles

- Available for egg-shaped profile cross sections from DN 400 to DN 1200 plus special profiles

Logging

The UV doc not only saves the recorded data as a list protocol and separate video file, but also records all relevant curing data including video files as a curing project. This means that all quality-relevant curing steps can be viewed 1 to 1 on the separate UV doc player.

Possible configurations

- UV compact system

- Light chain Standard (3600 Watt)

9 lamps of 400 Watt each for pipes from DN 150 to DN 500 incl. egg profiles

- UV compact system

- Booster Mini (9 x 650 Watt)

- Light chain Standard Plus 5850 Watt

9 lamps of 650 Watt each for pipes from DN 150 to DN 600 incl. egg profiles

- UV compact system

- Booster Medium (9 x 1000 Watt)

- Light chain Medium (9000 Watt)

3 x 3 lamps of 1000 Watt each for pipes from DN 650 to DN 1500 incl. egg profiles

- Control cabinet 1200 Professional

- UV drum 150 with cable lengths up to 200 m

- Booster Medium (9 x 1000 Watt)

- Light chain double core (8000 Watt)

2 x 4 lamps of 1000 Watt each for pipes from DN 650 to DN 1200 incl. egg profiles

- Control cabinet 1200 Professional

- UV drum 300 with cable lengths up to 320 m

- Booster Maxi (9 x 2000 Watt)

- Light chain Maxi (18000 Watt)

3 x 3 lamps of 2000 Watt each for pipes from DN 1200 to DN 1500

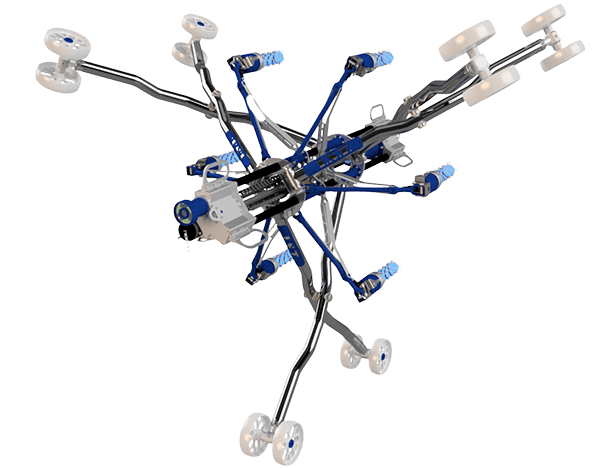

Power LIGHT Double Six Core

More power for liners of dimensions DN 1000 to DN 1600

The chain consists of two identically constructed, self-sufficient cores. Each core has six radially arranged UV lamps with 1,200 watts each.

The installation of wheelsets of different lengths allows the adaptation to different pipe diameters.

To make sure that the chain passes quickly through the packer into the liner, it should be as small as possible. To achieve this, the wheel set and emitters can be retracted.

Once the chain is in the liner, the wheels are extended and lift the cores upwards. At the same time, the emitters extend in the direction of the pipe wall in order to irradiate the laminate with the highest possible light intensity. A display on the panel provides information about the current extension position. In the event of motor overload, the movements are stopped.

- Use in confined installation conditions

- Easy and fast insertion into the liner

- Low weight

- Total output 14,400 W (2 x 6 x 1,200 W)

| Double Six Core | Technical data | |

|---|---|

| Pipe dimensions: | Circular profile: DN 1000 to DN 1600 Oval profile: DN 800/1200 to 1200/1800 |

| Number of UV spotlights: | 6 per core |

| Number of cores: | 2 pc. |

| UV spotlight power: | 1,200 W |

| Total power: | 14,400 W |

| IR sensors: | 3 pc. |

| Ambient air sensor: | 1 pc. |