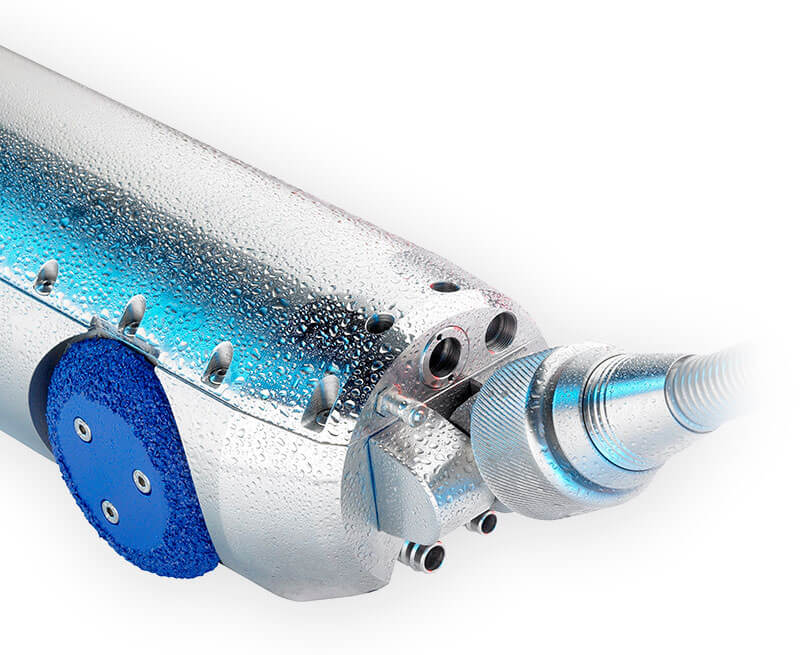

Power CUTTER 200

The innovative, multifunctional robot of the very highest qualityThe versatile milling robot that is way ahead of its time.

This robot features a functional design without any supply lines on the unit, the endless circling of the robot’s arm is not interrupted by a stopper. In addition, the PC 200 visualizes the position of the arm and is equipped with a CAN bus control.

Features

Strain relief via screw connection

Connection option for additional components

Rear camera

- CCD camera

- High resolution wide angle optics

- LED lighting

- Pressurized

Carriage

- Slim design

- Powerful carriage drive

- Integrated hydraulics for arm lift

- Milling tool swivel

- Internal supply lines

- Tilt measurement

Degrees of freedom

- Robot arm with lifting and lowering function

- Circling of robot arm left and right

- Forward and reverse travel

- Swivel tool holder back and forth

Robot arm

- Lifting 90° upwards, lowering 20° downwards

- Endless circles without stop

- Air motor/milling head with a swivel range of 100°

- Sensor-based monitoring of pressure, humidity and arm position

Front camera

- High-resolution CCD color camera

- Powerful LED lighting

- Large swivel range (200°)

- Electrical focusing

- Pressurized

- Easy assembly/disassembly

- 10x optical zoom in the PRO version

Mechanical features

No supply lines on the device!

- No external air hose for the air motor on the housing

- No external water hose for camera cleaning on the housing

- No hydraulic lines on the housing

- No cables for camera supply on the housing

This robot design allows endless circling without mechanical stop of the arm. No damage to supply lines for hydraulic cylinder, air motor and camera.

Electronic surveillance

- Pressure sensor in the carriage

- Temperature sensor in the carriage

- Humidity sensor in the carriage

CAN bus communication

- Storage and recovery of connection positions (worldwide patented)

- Secure data transmission between the controller and the connected components

- Modular structure thanks to CAN bus.

- Easy integration of additional components into the system

Visualization

- Display of pressure, temperature and humidity in the device

- Arm up / down position

- Arm circling

- Tool swivel position

Technical data

Operating range

DN 200 – DN 700

Total length

Arm length

CIRCUMFERENCE Ø

Weight

Subject to technical changes and further developments.

Control system

Sensory monitoring is a highlight that has a number of advantages in practice. Inclination sensors determine the axial and radial inclination of the carriage, sensors monitor pressure and humidity in the carriage and angle sensors monitor the position of the components in relation to each other as well as the arm’s circling function. The controls provide the following features

- Universal supply voltage 115 V/ 230 V

- Compact design (width 19″, height 3HE)

- Communication via CAN bus

- External control panel with display

- Control of all movements by joystick

- Switchable video inputs and outputs

- Parameter visualization

- Display of lateral and longitudinal inclination

- Storage and recall of parameters

- Weight approx. 8 kg

Supply technology

Cable drum

- Supply voltage 115 V/ 230 V

- 140 m special cable; tensile force > 400 kg

- 220 m special cable; tensile force > 400 kg

- Automatic winding and unwinding of the cable

- Forced guidance of the cable during winding and unwinding

- Integrated meter display

- Adjustable cable tension

- Adjustable cable speed

- Manual reeling of the cable possible

- Weight approx. 39 kg

Hose reel

- 100 m or 200 m twin hose for air and water supply

- Manual rewind or automatic unwind

- Rotating joint for air and water

- Sturdy tubular steel frame

- Weight approx. 56 kg

Air motors

All motors are equipped with an M14 connection thread.

Power-Line

- Power: 1,400 W

- Speed: 4,300 1/min

- Torque: 12.2 Nm

- Air consumption: 1,650 l/min

Basic-Line

- Power: 1,200 W

- Speed: 10,800 1/min

- Torque: 5.5 Nm

- Air consumption: 1,500 l/min

(Basic configuration)

Eco-Line

- Power: 860 W

- Speed: 18,000 1/min

- Torque: 4 Nm

- Air consumption: 1,050 l/min

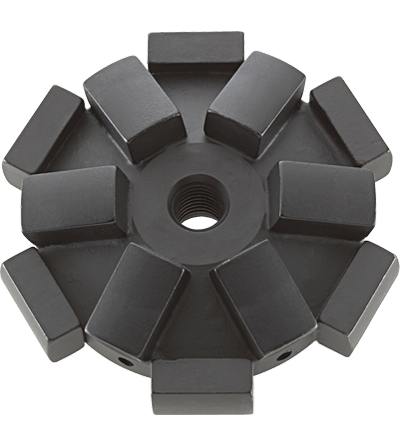

Tools

Diamand milling heads

Field of application: mineral materials such as concrete and stoneware. Can also be used for processing of cast materials to a limited extent.

Milling heads from the Epulo series

Field of application: all non-mineral materials such as liner material, roots and plastics. ATTENTION: The milling heads of the Epulo series may not be used for machining steel or for cast-iron materials!

Power TOOL KATANA

High-performance milling heads for the Power CUTTER 200

The perfect tools for unprecedented drilling and milling performance, especially when it comes to very hard materials with impressive results. Within just a few seconds, these extremely high quality tools can drill holes of several centimeters with subsequent milling. The absolutely clean cutting pattern further demonstrates the product’s superiority over conventional milling heads.

Universal base

Universal base for mobile use to supply the Power CUTTER 200 E / 200 / 150.

Comprehensive solution for the provision of all required media with integrated air treatment, power and water supply including crane system. Can be quickly assembled and disassembled, including the control panel.

Highest pressure water jetting